Slurry Wall Concrete Mix Design

Either value is achievable with the right mix of.

Slurry wall concrete mix design. Typically sb backfill has a permeability in the range of 10 6 to 10 8 cm sec. A slurry wall is a civil engineering technique used to build reinforced concrete walls in areas of soft earth close to open water or with a high groundwater table. This mixture is capable of filling all voids in irregular excavations and hard to reach places such as under undercuts of. Cement bentonite slurry wall mix design christopher r.

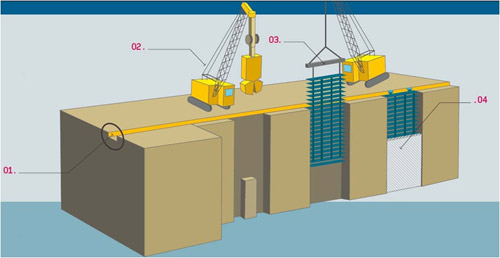

Icos constructed the first structural slurry wall in the late 1950s for the milan metro puller 1996. This technique is typically used to build diaphragm water blocking walls surrounding tunnels and open cuts and to lay foundations. In particular the concrete slump should be 8 inches 1 inch for tremie or slurry construction and 7 inches 1 inch for all other conditions. Department of the interior bureau of reclamation july 2014.

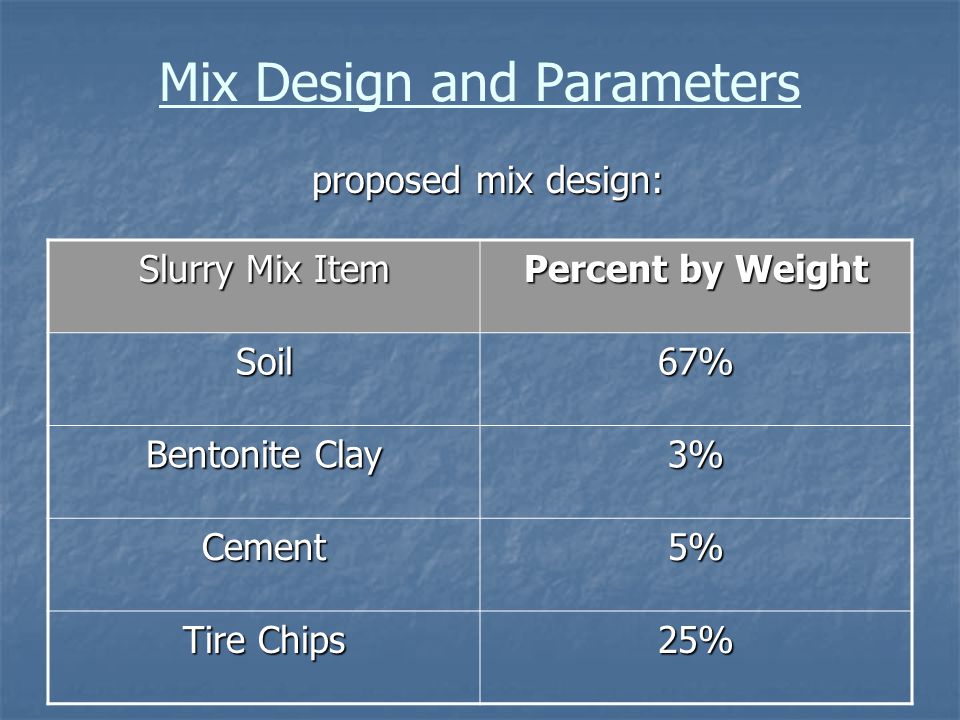

Day äbsträct ä cement bentonite cb slurry cut off wall is a variation of the slurry wall process that is used to create an underground barrier to stop the lateral flow of ground water and other fluids. The ideal texture of concrete slurry is thick and pasty with a consistency similar to tempera paint. If the slurry is too runny or too thick it will not adequately adhere to the concrete surface and will prevent bonding between the concrete layers. Environmental projects often require a permeability less than 1 x 10 7 cm sec but a levee or dewatering project may require a permeability less than 1 x 10 6 cm sec.

Flowable fill concrete is a self compacting cementitious slurry consisting of a mixture of fine aggregate or filler water and cementitious material which is used as a fill or backfill in lieu of compacted soil backfill. Because of the relative simplicity. The most important property of sb backfill is a low permeability. R an steven r.

Concrete mix design and workability shall be consistent for tremie or pump placement. Introduction this guide was developed to assist designers in evaluating the suitability of concrete diaphragm walls slurry walls for earth support for project application to provide an understanding of common construction issues and provide guidance on construction inspection requirements. Design guide slurry wall december 2008 page 1 of 43 i. Concrete consolidation during placement.

The ratio for a basic concrete slurry mix is 1 or 2 parts portland cement to 1 part water. When combined with surecrete s color packs it allows design elements to match complement or contrast with the concrete piece.