Sheet Metal Quality Checklist

In fact research suggests that manufacturers spend 30 to 50 of their time.

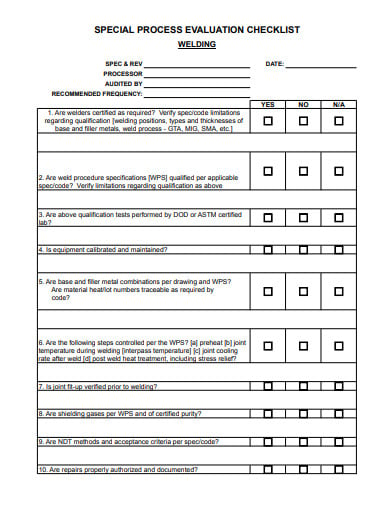

Sheet metal quality checklist. Determine if each 1x4 in. Check protective devices and warning signs. A checklist for quality seven questions to gauge quality in metal stamping suppliers. Welding procedures shall be qualified and approved in accordance with the applicable aws welding code s or specification s i e d1 1 d1 5 or aws b2 1 specification for welding procedure and.

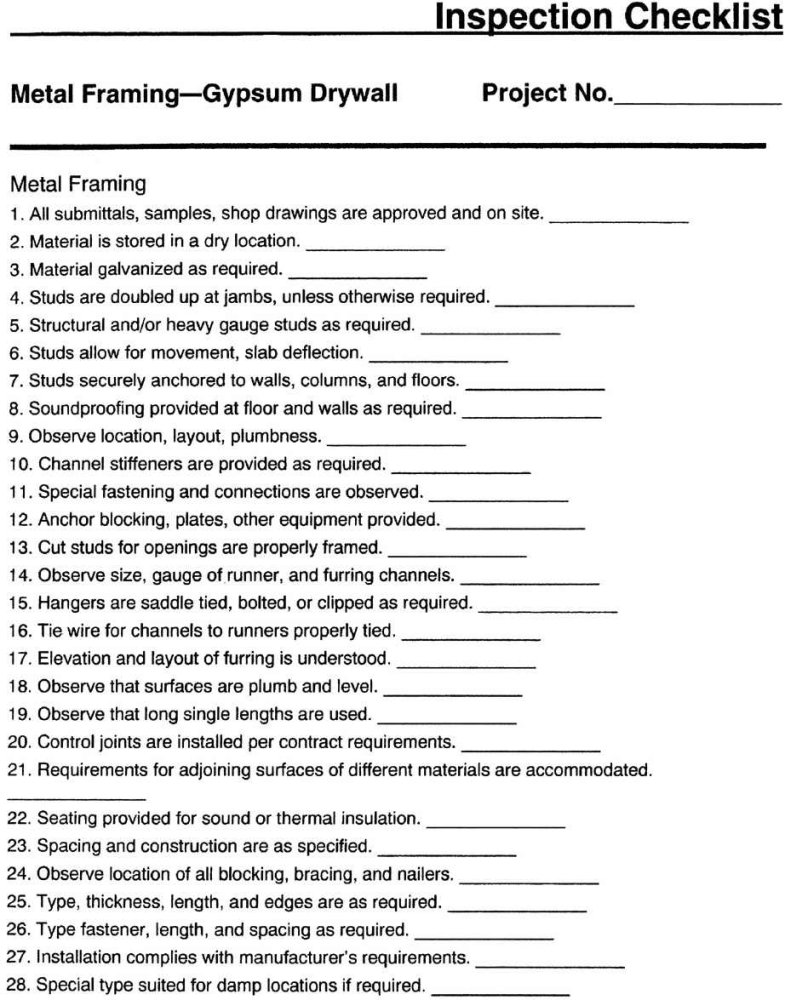

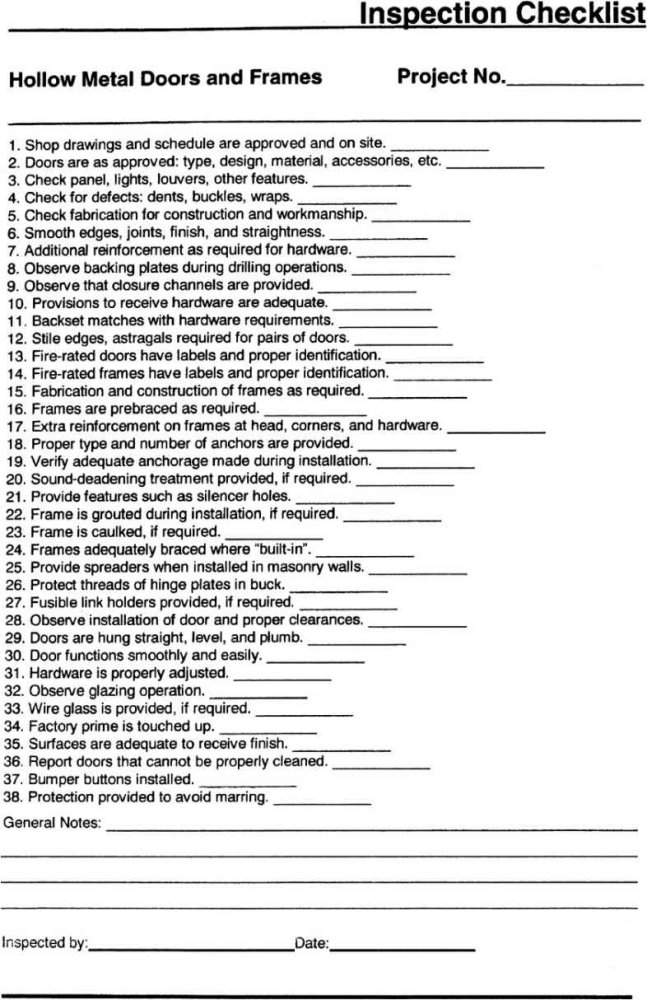

To manufacture sheet metal efficiently reduce errors and cut costs you have to apply the engineering principle of design for manufacturing dfm. Are painting operations and the application of adhesives remote from. Wall framing inspection checklist continued c. Download print or.

In shop and on site. The quality manager approves welding procedures before they can be used to fabricate metal. Www eesemi com all about semiconductor manufacturing. This steel fabrication quality control checklist is powered by dashpivot giving you new powers and controls over your checklists and quality management.

A high quality cupping test machine comes with a pre installed die and blank holder. Are arc welding and cutting operations shielded by noncombustible or. Dfm simplifies manufacturing sheet metal by considering design guidelines and tolerances that will ensure your component can actually be produced correctly. Itõs the 1 concern for oem engineering and purchasing managers when evaluating.

The punch has a polished hemispherical working surface. Placed at an angle from horizontal between 45 and 60 degrees. Statistics on quality related practices. If metal bracing is used then verify that the metal braces are installed and.

Metal inert gas mig and metal active gas mag welding. This drives down the resources available to the quality control process even though sheet metal parts are often used in the most demanding applications such as aerospace or automotive or in very large production runs all of which. Read microsoft 1 35. The value of quality quality.

The machine lets the. Engineers designing sheet metal enclosures and assemblies often end up redesigning them so they can be manufactured. Sheet metal design guidelines tolerances. Manufacturing sheet metal parts can be particularly difficult.

Quality control checklist metal fabrication golf cart batteries at sams marine 3 bank battery. International training institute for the sheet metal and. Sheet metal shop yes no n a. Flameproof shields to protect employees from direct arc rays.

Welding and cutting operations. The production cost per component is very low compared with other industries such as metal machining. Let into top and bottom plates and adjoining studs. It has the required gauges installed to ensure accurate measurement.